What is the Best Way to Cut Wood with a Laser Cutter?

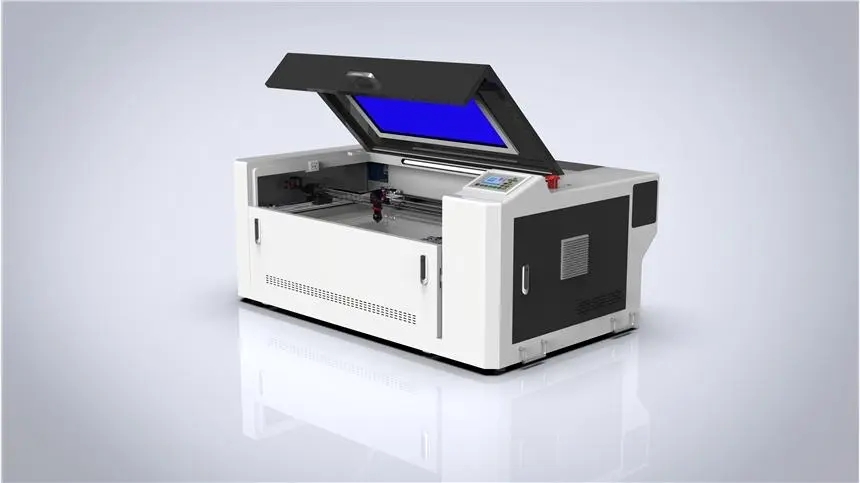

Laser cutters are advanced machines used in many industrial settings to precisely cut materials for a variety of applications. They are also used in certain hobby settings, such as woodworking and creating art out of wood. Utilizing a laser cutter for cutting wood can be a great way to create intricate designs and shapes that would be difficult to achieve with traditional tools. However, there are a few steps that must be followed to ensure the best possible results when cutting wood with a laser cutter.

Preparing the Wood

The first step in cutting wood with a laser cutter is to prepare the wood. It is important to ensure the wood is clean and dust-free, as any dirt or debris on the wood can interfere with the laser cutter’s operation. This process can be done either manually or with the use of a vacuum cleaner. Additionally, the wood should be secured onto the laser cutting bed with the appropriate clamps or other suitable tools to ensure it stays firmly in place during the cutting process.

Choosing the Right Laser Settings

The second step in cutting wood with a laser cutter is to choose the appropriate laser settings for the project. Care must be taken to choose the right power, speed, and focus settings for the job. The laser power must be set to an appropriate level to ensure the wood is cut through cleanly and accurately. The speed should be adjusted to an appropriate level so it does not exceed the rate at which the laser cutter is able to cool the wood. The focus should be adjusted to ensure the laser is cutting deep enough into the wood. It is important to note that the settings may need to be adjusted depending on the type and thickness of wood being cut.

Cleaning up the Cut

The final step in cutting wood with a laser cutter is to clean up the edges after the cut is complete. The laser cutter can generate a lot of heat and debris when cutting wood and this should be cleaned up with an appropriate brush. Additionally, it might be necessary to sand down any rough edges on the cut wood to create a smoother finish.

FAQs

Q: What is the best laser power for cutting wood?

A: The best laser power for cutting wood will depend on the type and thickness of the wood. Generally speaking, a lower laser power should be used for thin materials, while higher laser power should be used for thicker materials.

Q: How important is focus when cutting wood with a laser cutter?

A: Focus is very important when cutting wood with a laser cutter. It is important to adjust the focus so it is cutting deep enough into the wood. This will ensure an accurate and clean cut.

Q: What other tools are needed for cutting wood with a laser cutter?

A: Apart from the laser cutter itself, the tools needed for cutting wood with a laser cutter include clamps to secure the wood onto the cutting bed and a brush to clean up debris and rough edges after the cut is complete. A vacuum cleaner may also be required to keep the dust and debris off the wood before cutting.