The process of CO2 laser cutting has revolutionized the way nylon fabrication is done. This advanced technology has made it possible to create precise and intricate designs on nylon fabric with remarkable speed and accuracy. CO2 laser cutting has become an indispensable tool for manufacturers and designers working with nylon, providing them with unprecedented flexibility and efficiency in their production processes.

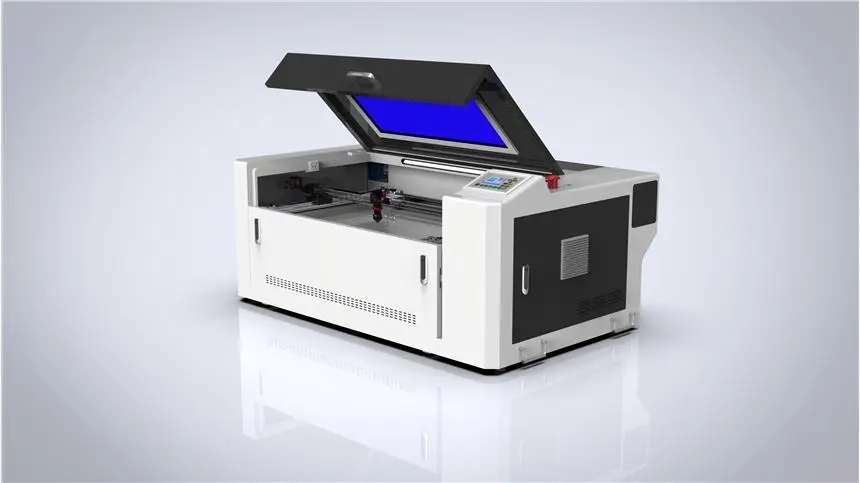

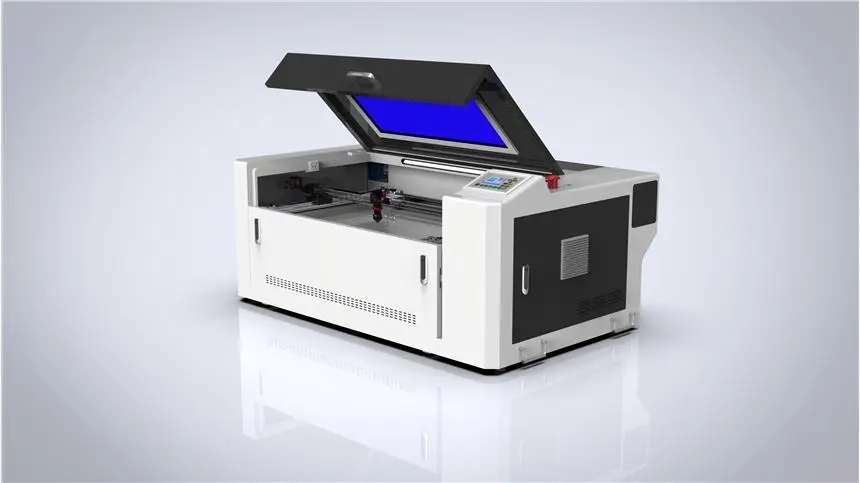

How does CO2 laser cutting work?

CO2 laser cutting works by using a high-powered laser to melt and vaporize the material being cut. The laser beam is focused and directed by a computer-controlled system, allowing for precise and clean cuts to be made on the nylon fabric. This method of cutting is extremely fast and produces minimal waste, making it an eco-friendly option for fabrication.

Benefits of CO2 laser cutting for nylon fabrication

CO2 laser cutting offers numerous advantages for nylon fabrication, including:

- Precision: The laser cutting process delivers extremely accurate results, allowing for the creation of intricate designs and patterns on nylon fabric.

- Speed: CO2 laser cutting is much faster than traditional cutting methods, reducing production time and increasing overall efficiency.

- Flexibility: The computer-controlled nature of CO2 laser cutting allows for easy customization and the ability to quickly switch between different designs and patterns.

- Minimal waste: The precise nature of CO2 laser cutting minimizes material waste, making it a cost-effective and eco-friendly option for nylon fabrication.

Applications of CO2 laser cutting in nylon fabrication

CO2 laser cutting is widely used in the production of a variety of nylon products, including apparel, accessories, and industrial components. Its ability to create intricate designs and patterns makes it an ideal choice for producing high-quality and visually appealing nylon fabric products.

FAQs

Q: Is CO2 laser cutting safe for nylon fabric?

A: Yes, CO2 laser cutting is safe for nylon fabric. The process produces minimal heat-affected zones and does not cause fraying or melting of the material, resulting in clean and precise cuts.

Q: Can CO2 laser cutting be used for different types of nylon fabric?

A: Yes, CO2 laser cutting is suitable for a wide range of nylon fabrics, including nylon 6, nylon 66, and nylon blends.

Q: What are the limitations of CO2 laser cutting for nylon fabrication?

A: While CO2 laser cutting is highly versatile, it may not be suitable for very thick or heavily dyed nylon fabrics. In such cases, alternative cutting methods may be more appropriate.

Q: Are there any environmental benefits of using CO2 laser cutting for nylon fabrication?

A: CO2 laser cutting produces minimal waste and consumes less energy compared to traditional cutting methods, making it an environmentally friendly choice for nylon fabrication.