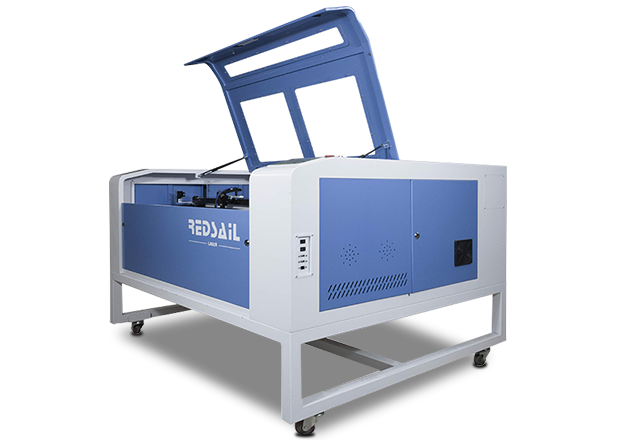

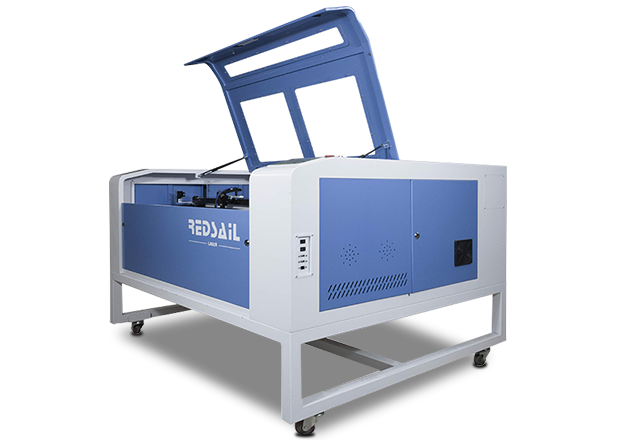

CO2 Laser Cutting: Achieving Precision with MDF

CO2 laser cutting is a popular method for cutting and engraving materials such as wood, plastic, and metal. It is especially useful for cutting MDF (medium-density fiberboard), a type of engineered wood product that is used in a variety of applications. MDF is a great material for laser cutting because it is easy to work with and produces precise, clean cuts.

How Does CO2 Laser Cutting Work?

CO2 laser cutting works by focusing a beam of light onto the material to be cut. The beam is generated by a laser, which is a device that produces a highly concentrated beam of light. The beam is then directed onto the material, which is heated up by the laser and cut or engraved.

Advantages of CO2 Laser Cutting with MDF

CO2 laser cutting with MDF has several advantages over other cutting methods. It is a fast and precise method of cutting, and it produces clean, smooth edges. It is also a cost-effective method, as it requires less energy and fewer materials than other cutting methods. Additionally, it is a safe method of cutting, as it does not produce any hazardous fumes or dust.

Tips for Achieving Precision with CO2 Laser Cutting

To achieve the best results with CO2 laser cutting, it is important to use the right settings and materials. The laser should be set to the correct power and speed for the material being cut. Additionally, the material should be of the correct thickness and quality. It is also important to use the right type of laser for the job, as some lasers are better suited for certain materials than others.

FAQs

What is CO2 laser cutting?

CO2 laser cutting is a method of cutting and engraving materials such as wood, plastic, and metal. It works by focusing a beam of light onto the material to be cut, which is then heated up by the laser and cut or engraved.

What are the advantages of CO2 laser cutting with MDF?

CO2 laser cutting with MDF has several advantages over other cutting methods. It is a fast and precise method of cutting, and it produces clean, smooth edges. It is also a cost-effective method, as it requires less energy and fewer materials than other cutting methods. Additionally, it is a safe method of cutting, as it does not produce any hazardous fumes or dust.

What tips should I follow to achieve precision with CO2 laser cutting?

To achieve the best results with CO2 laser cutting, it is important to use the right settings and materials. The laser should be set to the correct power and speed for the material being cut. Additionally, the material should be of the correct thickness and quality. It is also important to use the right type of laser for the job, as some lasers are better suited for certain materials than others.