CO2 Laser Cutting: The Future of Polyimide Fabrication

Polyimide is a type of plastic that is used in a variety of applications, from medical devices to aerospace components. It is a highly durable material that is resistant to heat, chemicals, and abrasion. However, traditional cutting methods such as mechanical cutting and waterjet cutting can be time-consuming and expensive.

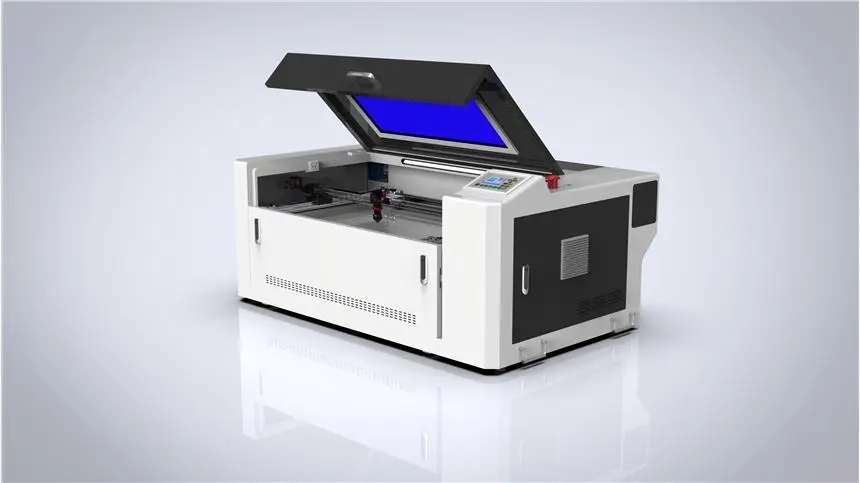

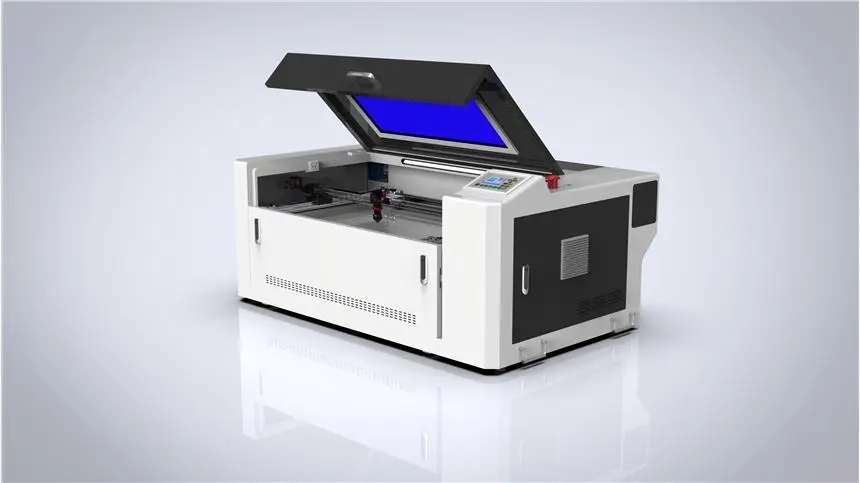

What is CO2 Laser Cutting?

CO2 laser cutting is a process that uses a beam of high-energy laser light to cut through polyimide and other materials. The laser beam is focused onto the material, which is then vaporized or melted away. This process is fast, precise, and cost-effective, making it an ideal choice for polyimide fabrication.

Advantages of CO2 Laser Cutting

CO2 laser cutting offers several advantages over traditional cutting methods. It is faster and more precise, allowing for complex shapes and intricate details to be cut with ease. It also produces a cleaner cut, with minimal burrs or rough edges. Additionally, CO2 laser cutting is more cost-effective than other methods, as it requires less energy and fewer consumables.

Applications of CO2 Laser Cutting

CO2 laser cutting is used in a variety of industries, including automotive, aerospace, medical, and electronics. It is used to cut polyimide for a variety of applications, such as circuit boards, medical implants, and aerospace components. It is also used to cut other materials, such as metals, plastics, and wood.

Conclusion

CO2 laser cutting is the future of polyimide fabrication. It is fast, precise, and cost-effective, making it an ideal choice for a variety of applications. With its many advantages, it is no wonder that CO2 laser cutting is becoming increasingly popular in the manufacturing industry.

FAQs

What is polyimide?

Polyimide is a type of plastic that is used in a variety of applications, from medical devices to aerospace components. It is a highly durable material that is resistant to heat, chemicals, and abrasion.

What is CO2 laser cutting?

CO2 laser cutting is a process that uses a beam of high-energy laser light to cut through polyimide and other materials. The laser beam is focused onto the material, which is then vaporized or melted away.

What are the advantages of CO2 laser cutting?

CO2 laser cutting offers several advantages over traditional cutting methods. It is faster and more precise, allowing for complex shapes and intricate details to be cut with ease. It also produces a cleaner cut, with minimal burrs or rough edges. Additionally, CO2 laser cutting is more cost-effective than other methods, as it requires less energy and fewer consumables.