CO2 Laser Cutting: The Future of Rubber Manufacturing

Rubber manufacturing is an industry that has been around for centuries. It is used in a variety of applications, from automotive parts to medical devices. In recent years, the industry has seen a shift towards the use of laser cutting technology to produce rubber parts. This technology has revolutionized the way rubber parts are produced, allowing for faster production times and higher quality parts.

What is CO2 Laser Cutting?

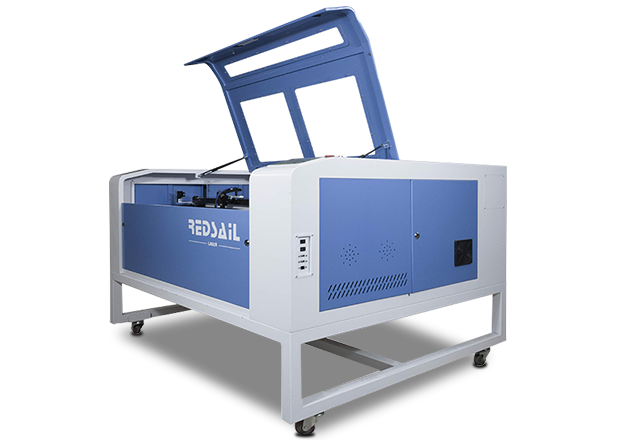

CO2 laser cutting is a process that uses a laser beam to cut through rubber material. The laser beam is generated by a CO2 laser, which is a type of gas laser. The laser beam is focused on the rubber material, which is then heated and vaporized. This process allows for precise cutting of the rubber material, creating parts with intricate shapes and details.

Benefits of CO2 Laser Cutting

CO2 laser cutting offers a number of benefits for rubber manufacturing. The process is fast and efficient, allowing for faster production times. It also produces parts with high accuracy and detail, which is important for producing parts with complex shapes and designs. Additionally, the process is clean and does not produce any hazardous waste, making it an environmentally friendly option.

The Future of Rubber Manufacturing

CO2 laser cutting is quickly becoming the preferred method of rubber manufacturing. The technology is fast, efficient, and produces high-quality parts. As the technology continues to improve, it is likely that more rubber manufacturers will begin to adopt it. This will lead to faster production times and higher quality parts, making rubber manufacturing more efficient and cost-effective.

FAQs

What is CO2 laser cutting?

CO2 laser cutting is a process that uses a laser beam to cut through rubber material. The laser beam is generated by a CO2 laser, which is a type of gas laser. The laser beam is focused on the rubber material, which is then heated and vaporized. This process allows for precise cutting of the rubber material, creating parts with intricate shapes and details.

What are the benefits of CO2 laser cutting?

CO2 laser cutting offers a number of benefits for rubber manufacturing. The process is fast and efficient, allowing for faster production times. It also produces parts with high accuracy and detail, which is important for producing parts with complex shapes and designs. Additionally, the process is clean and does not produce any hazardous waste, making it an environmentally friendly option.

What is the future of rubber manufacturing?

CO2 laser cutting is quickly becoming the preferred method of rubber manufacturing. The technology is fast, efficient, and produces high-quality parts. As the technology continues to improve, it is likely that more rubber manufacturers will begin to adopt it. This will lead to faster production times and higher quality parts, making rubber manufacturing more efficient and cost-effective.