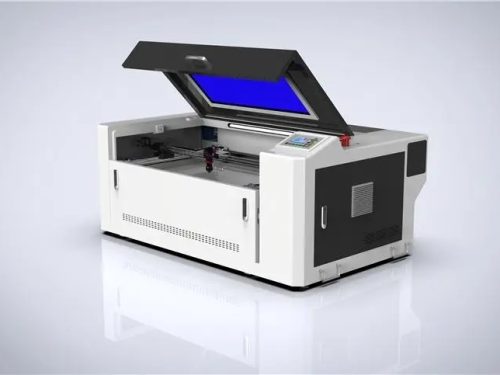

CO2 laser engraving machine is a engraving machine that uses CO2 laser technology. This type of laser equipment belongs to a universal model, with a rear focusing method, small size, and high integration level.

The principle of laser engraving is that the laser beam is transmitted and focused on the material surface through an optical mechanism, and the material at the point of action of the high-energy density laser beam rapidly vaporizes, forming pits. Using a computer to control the X-y console to drive the laser head to move and control the laser switch according to the requirements, the image information processed by the software has been stored in a certain way in the computer. When the information is sequentially read from the computer, the laser head scans back and forth along the scanning trajectory from left to right, from top to bottom, row by row. Whenever a “1” point is scanned, the laser is turned on, and when a “0” point is scanned, the laser is turned off. The computer stores information in binary format, which coincides with the two states of the laser switch.

The CO2 laser engraving machine is suitable for marking the vast majority of non-metallic materials, such as paper packaging, plastic products, label paper, leather fabrics, glass ceramics, resin plastics, bamboo and wood products, PCB boards, etc.

Advantages of CO2 laser engraving machine processing:

1. Wide range: Carbon dioxide laser can carve and cut almost any non-metallic material. And the price is low!

2. Safe and reliable: Adopting non-contact processing, it will not cause mechanical compression or stress on the material. No “knife marks” and no damage to the surface of the machined parts; Will not deform the material;

3. Accurate and meticulous: the machining accuracy can reach 0.02mm;

4. Economical and environmentally friendly: The diameter of the beam and spot is small, usually less than 0.5mm; Cutting and processing saves materials, ensuring safety and hygiene;

5. Consistent effect: Ensure that the processing effect of the same batch is completely consistent.

6. High speed and speed: It can immediately perform high-speed carving and cutting according to the computer output pattern.

7. Low cost: Not limited by the quantity of processing, laser processing is cheaper for small batch processing services.