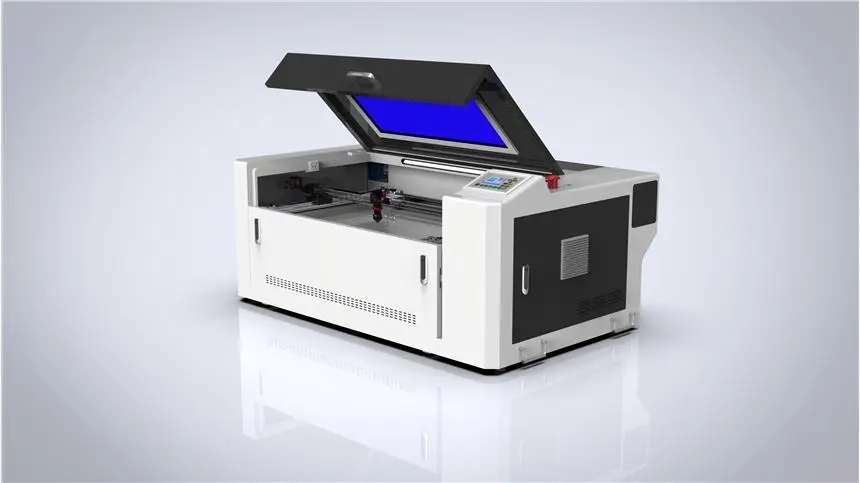

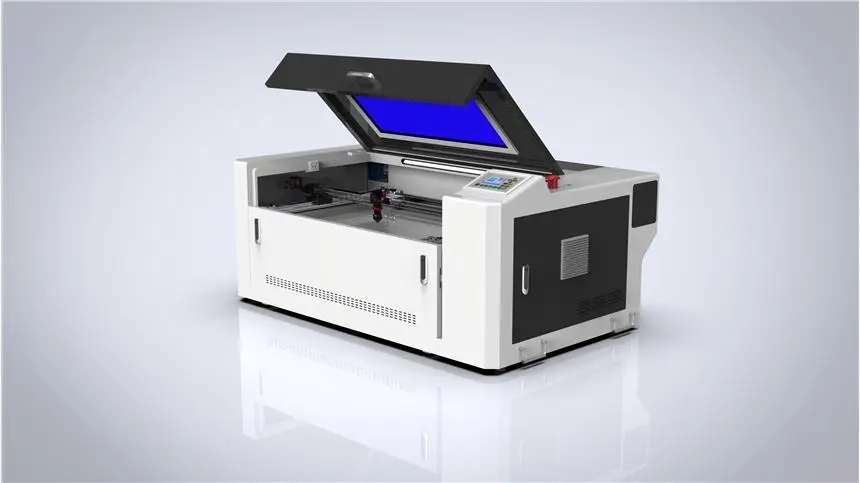

CO2 laser cutters are an essential tool for many industries, allowing for precision cutting and engraving on a variety of materials. However, like any piece of machinery, CO2 laser cutters can experience issues that can slow down production and affect the quality of the cuts.

Common CO2 Laser Cutter Issues

1. Inconsistent Cutting

If your CO2 laser cutter is producing inconsistent cuts, it could be a sign of a misaligned laser beam. Check the alignment of the mirrors and the laser beam to ensure they are properly calibrated.

2. Burn Marks on Material

Burn marks on the material being cut can be caused by a variety of issues, including incorrect settings or dirty optics. Make sure to clean the optics regularly and adjust the settings to prevent burn marks.

3. Power Supply Problems

If your CO2 laser cutter is experiencing power supply issues, it could be due to faulty wiring or a malfunctioning power supply unit. Check the wiring for any damage and test the power supply unit to ensure it is functioning properly.

How to Fix CO2 Laser Cutter Issues

When it comes to fixing CO2 laser cutter issues, it is important to identify the root cause of the problem and address it accordingly. Regular maintenance and cleaning of the machine can help prevent many common issues from occurring. In addition, staying on top of regular calibration and alignment checks can ensure that your CO2 laser cutter is operating at its best.

If you are unable to resolve the issue on your own, it may be necessary to seek professional assistance. A qualified technician can diagnose and repair any issues with your CO2 laser cutter, getting you back up and running in no time.

FAQs

Q: How often should I clean the optics of my CO2 laser cutter?

A: It is recommended to clean the optics of your CO2 laser cutter at least once a week to prevent dirt and debris from affecting the quality of the cuts.

Q: What should I do if my CO2 laser cutter is producing inconsistent cuts?

A: First, check the alignment of the mirrors and the laser beam to ensure they are properly calibrated. If the issue persists, it may be necessary to have a professional technician inspect and repair the machine.

Q: Can I perform maintenance on my CO2 laser cutter myself?

A: While basic maintenance tasks such as cleaning the optics can be performed by the user, more complex maintenance and repairs should be left to a qualified technician to ensure the safety and integrity of the machine.

Don’t let CO2 laser cutter issues slow you down. By staying on top of regular maintenance and addressing any issues promptly, you can keep your CO2 laser cutter operating at its best and avoid costly downtime.