Introduction

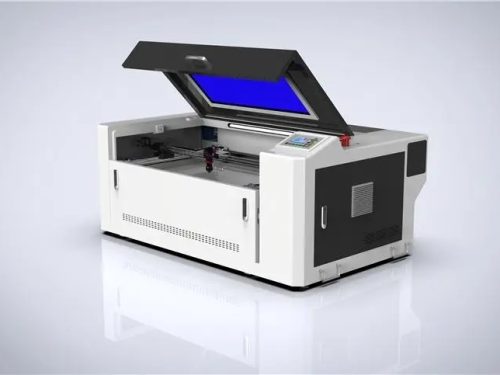

A 100W CO2 laser engraver is a powerful tool that can be used for a variety of applications, including cutting and engraving materials such as wood, acrylic, and leather. To ensure that your laser engraver continues to operate at peak performance, it’s important to properly maintain and care for the machine. Here are some tips for maintaining a 100W CO2 laser engraver.

Cleaning and Lubrication

Regular cleaning and lubrication are essential for keeping your laser engraver running smoothly. Clean the lens and mirrors regularly to remove any dust or debris that may have accumulated. Use a soft, lint-free cloth and isopropyl alcohol to gently wipe the lens and mirrors clean. Additionally, be sure to lubricate the rails and bearings to prevent excessive wear and tear on the machine’s moving parts.

Checking for Wear and Tear

Periodically inspect the machine for any signs of wear and tear. Check for loose screws, belts, or other components that may need to be tightened or replaced. It’s also important to regularly check the water cooling system to ensure that it is functioning properly.

Calibration

Calibrating your laser engraver is important for ensuring that it continues to produce accurate and precise cuts and engravings. Make sure to calibrate the machine regularly, particularly after any significant changes in temperature or humidity.

FAQs

How often should I clean the lens and mirrors?

It’s recommended to clean the lens and mirrors of your laser engraver at least once a week, or more frequently if the machine is used heavily.

What type of lubricant should I use for the rails and bearings?

A light machine oil or lithium grease is generally suitable for lubricating the rails and bearings of a laser engraver.

How do I know if the water cooling system is working properly?

Check the temperature of the water in the cooling system to ensure that it is within the recommended range. Additionally, listen for any unusual noises or vibrations coming from the water pump.

In conclusion, by following these maintenance tips, you can help to ensure that your 100W CO2 laser engraver continues to operate at its best. Regular cleaning, lubrication, and calibration can go a long way in extending the life of your machine and ensuring that it continues to produce high-quality results.