Laser etching is a non-contact technology used to identify or etch high-quality one-dimensional or two-dimensional code, multiline text, batch number, batch number, logo, traceability code and other necessary information on various types of products and packaging for identification. The laser identification etching process can accurately change the target material area on the packaging or product surface to create a clear and visible code. This process can prevent important printed information from being blurred and unreadable during or after application.

Laser etching is needed in many industries, including aerospace, automotive, extrusion molding and pharmaceutical industries. Laser etching can be used for identification on various materials, including metal, coated or painted metal, glass and various types of plastics. Different materials require different power levels of lasers. Choosing the correct power will have a direct impact on the generated code. Users must cooperate with laser system manufacturers to obtain efficient systems. For laser etching of various materials, it is also necessary to install a smoke exhaust system to protect production line workers.

Laser etching system has many important advantages over other identification technologies, including very consistent identification quality and durable identification. For different manufacturers, another significant advantage of the laser engraving machine is that it can run at a very high speed, which will directly affect the production efficiency, and under the guidance of the beam controller, the target moving on the production line can be identified. In addition, because there is no need to use ink or solvent, the demand for consumables that directly affect the production cost is reduced. There is no need to replace ink, reduce the maintenance demand, and significantly reduce the impact of users on the environment.

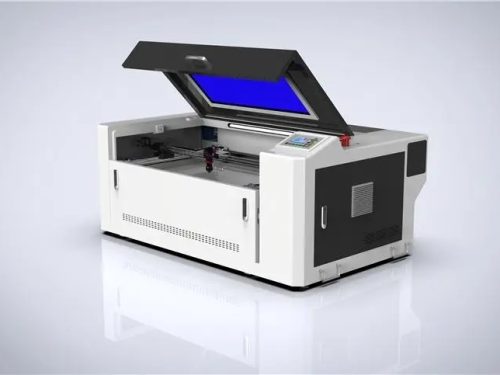

The laser etching machines currently used include various CO2, infrared and ultraviolet laser systems. A series of machines with different output power (such as optical fiber laser printer) can cope with various materials to be identified and different packaging or product applications. In addition, it provides a variety of laser accessories, including lenses and beam guiding devices, which can simplify the integration of laser engraving machine and production line configuration, and significantly improve the performance of laser printer.

The flexibility, accuracy and durability of laser marking are particularly important for the packaging of drugs and tobacco products. This kind of packaging needs to have a unique serialization code to ensure authenticity, tamper-proof and easy traceability. The reliability and high speed of laser marking also make it an important equipment in the high-yield beverage production line. A wide range of CO2 laser lenses, power and technology types support successful laser etching on glass and most plastics. Infrared laser coding machine is used to create identification on aluminum cans, and can provide clear and lasting coding on cans of various colors.