The Future of Manufacturing: Metal CO2 Laser Cutting

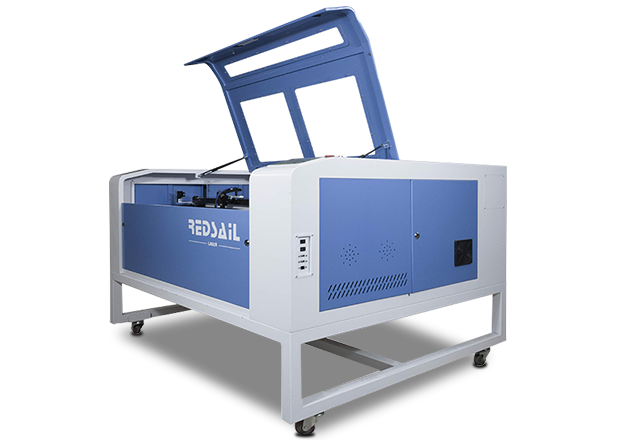

Manufacturing is an ever-evolving industry, and metal CO2 laser cutting is one of the most advanced technologies available today. This cutting process uses a laser beam to cut through metal, creating precise and intricate shapes with a high degree of accuracy. It is used in a variety of industries, from automotive to aerospace, and is becoming increasingly popular due to its cost-effectiveness and efficiency.

How Does Metal CO2 Laser Cutting Work?

Metal CO2 laser cutting works by focusing a beam of light onto a metal surface. The beam is generated by a laser, which is a device that produces a highly concentrated beam of light. The laser beam is then directed onto the metal surface, where it melts, vaporizes, or burns away the material. This process is highly precise and can be used to create intricate shapes and patterns.

Advantages of Metal CO2 Laser Cutting

Metal CO2 laser cutting offers a number of advantages over traditional cutting methods. It is faster and more accurate than traditional methods, and it can be used to create complex shapes and patterns. It is also more cost-effective than other cutting methods, as it requires less energy and fewer materials. Additionally, it is a clean process, as it does not produce any hazardous waste or fumes.

The Future of Metal CO2 Laser Cutting

The future of metal CO2 laser cutting looks bright. As the technology continues to improve, it will become even more cost-effective and efficient. Additionally, the use of lasers in manufacturing is expected to increase, as they are becoming more widely available and affordable. This will open up new possibilities for manufacturers, allowing them to create more complex and intricate designs with greater precision.

FAQs

What is metal CO2 laser cutting?

Metal CO2 laser cutting is a process that uses a laser beam to cut through metal, creating precise and intricate shapes with a high degree of accuracy.

What are the advantages of metal CO2 laser cutting?

Metal CO2 laser cutting offers a number of advantages over traditional cutting methods. It is faster and more accurate than traditional methods, and it can be used to create complex shapes and patterns. It is also more cost-effective than other cutting methods, as it requires less energy and fewer materials. Additionally, it is a clean process, as it does not produce any hazardous waste or fumes.

What is the future of metal CO2 laser cutting?

The future of metal CO2 laser cutting looks bright. As the technology continues to improve, it will become even more cost-effective and efficient. Additionally, the use of lasers in manufacturing is expected to increase, as they are becoming more widely available and affordable. This will open up new possibilities for manufacturers, allowing them to create more complex and intricate designs with greater precision.