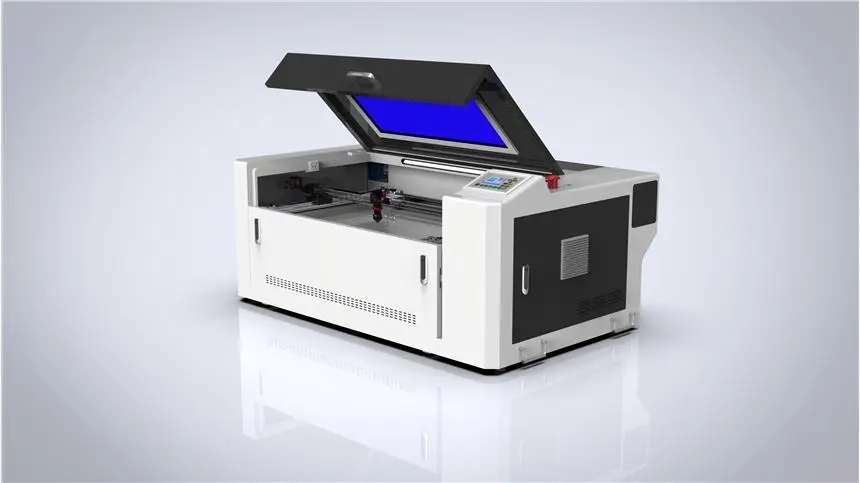

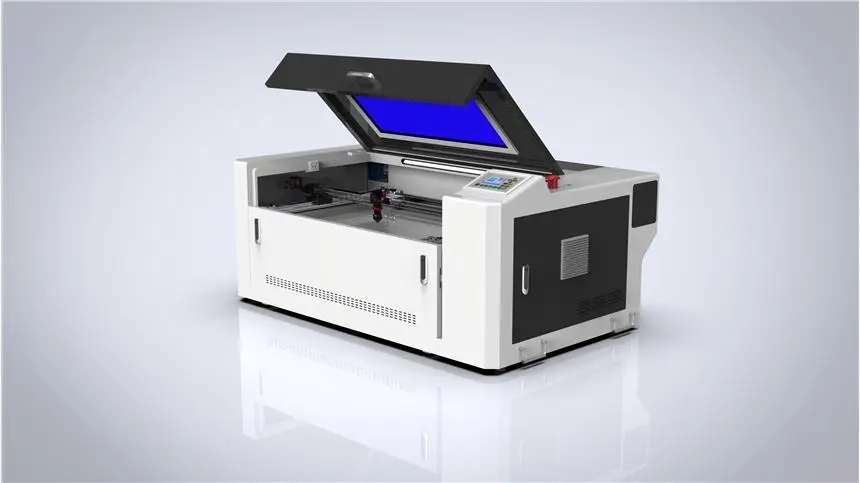

Troubleshooting Tips for CO2 Laser Cutting Machine Repair

CO2 laser cutting machines are used in a variety of industries for cutting and engraving materials. They are reliable and efficient, but like any machine, they can experience problems. If you are having trouble with your CO2 laser cutting machine, here are some troubleshooting tips to help you get it back up and running.

Check the Power Supply

The first step in troubleshooting your CO2 laser cutting machine is to check the power supply. Make sure the power cord is securely plugged into the machine and the outlet. If the power cord is loose or damaged, it may need to be replaced. Also, check the circuit breaker to make sure it is not tripped.

Check the Laser Tube

The laser tube is the most important part of the CO2 laser cutting machine. If the laser tube is not working properly, the machine will not be able to cut or engrave. Check the laser tube for any signs of damage or wear. If the laser tube is damaged, it will need to be replaced.

Check the Mirrors and Lens

The mirrors and lens are responsible for directing the laser beam to the material being cut or engraved. Check the mirrors and lens for any signs of damage or wear. If the mirrors or lens are damaged, they will need to be replaced.

Check the Software

The software is responsible for controlling the laser cutting machine. Check the software for any errors or glitches. If the software is not working properly, it may need to be reinstalled or updated.

Check the Air Supply

The air supply is responsible for cooling the laser tube and other components of the machine. Check the air supply for any signs of damage or wear. If the air supply is damaged, it will need to be replaced.

FAQs

What should I do if my CO2 laser cutting machine is not working?

If your CO2 laser cutting machine is not working, the first step is to check the power supply. Make sure the power cord is securely plugged into the machine and the outlet. Also, check the circuit breaker to make sure it is not tripped. If the power supply is working, check the laser tube, mirrors, lens, software, and air supply for any signs of damage or wear.

How often should I check the laser tube?

The laser tube should be checked regularly for any signs of damage or wear. It is recommended to check the laser tube at least once a month.