In the early days, the thickness of optical fiber laser cutting plates may be limited to 20 mm for carbon steel and 12 mm for stainless steel. With the development of intelligent processing, the market demand for laser cutting continues to increase. People have a higher awareness of laser cutting machines and higher expectations. This expectation is not only to be able to cut, but also to ensure good and fast cutting, especially in terms of cutting thickness. The first revolutionary change in the sheet metal processing field caused by the 10000 watt optical fiber laser cutting is the continuous improvement of the machinable thickness of different materials:

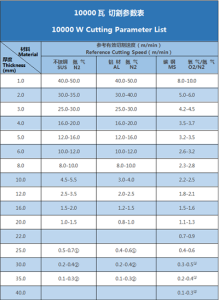

What are the cutting parameters of the 10000w laser cutting machine? At present, the stainless steel plate of 10000W laser cutting machine can reach 35mm, and the carbon steel plate can reach 40mm. With the introduction of 12000W and 15000W optical fiber laser cutting machines, the thickness limit of material cutting will continue to be broken.

However, it should be noted that ① it means simple graphics, low requirements and small batches; ② It means that proofing can be done and cutting is limited. The cutting effect and speed will also be affected due to material differences or personnel operation differences.

In addition to the improvement of cutting thickness, the cutting efficiency of ten thousand watt laser cutting in the field of thin and medium plate is also improved by several times. When cutting stainless steel and carbon steel plates with a thickness of 3-10mm, the cutting speed of 10000w laser cutting machine is more than twice that of 6000w. The efficiency of ten thousand watt laser cutting sheet metal has been greatly improved beyond people’s imagination, which is also the main reason why high-power laser cutting machines are popular in the sheet metal market.