Introduction

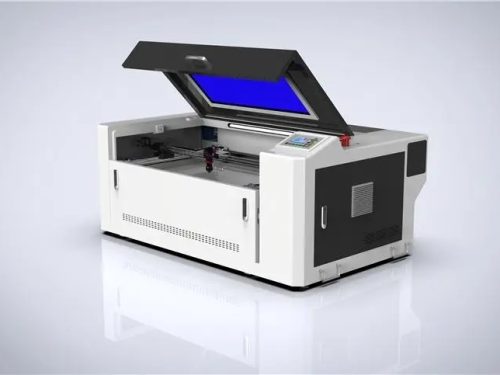

When it comes to purchasing a laser engraver, there are several important factors to consider. Whether you are a hobbyist looking for a small machine for personal use or a business owner in need of a high-powered industrial engraver, it’s important to know what to look for in a laser engraver before making a purchase. This buyer’s guide will outline the key features and considerations to keep in mind when shopping for a laser engraver.

Key Features to Consider

When shopping for a laser engraver, there are several key features to consider:

Power and Speed

The power and speed of a laser engraver will determine its capabilities. Higher wattage lasers offer more power and faster engraving speeds, which is important for cutting through thicker materials and engraving larger designs. Consider the types of projects you plan to undertake and choose a laser engraver with an appropriate power and speed rating.

Work Area Size

The size of the work area on a laser engraver will dictate the maximum dimensions of the items that can be engraved. If you plan to work on larger projects, be sure to choose a machine with a sufficient work area size.

Software and Compatibility

Consider the software that accompanies the laser engraver and ensure that it is compatible with your computer operating system. It’s also important to look for a machine that can work with a variety of design file formats, such as .ai, .dxf, .bmp, and .jpeg.

Additional Features

Some laser engravers come with additional features such as autofocus capabilities, rotary attachments for engraving cylindrical objects, and ventilation systems for removing fumes and smoke. Consider which additional features are important for your specific needs.

FAQs

What materials can be engraved with a laser engraver?

Laser engravers can be used to engrave a wide range of materials, including wood, plastic, glass, leather, metal, and more.

Can a laser engraver also cut materials?

Yes, many laser engravers are capable of cutting through materials such as wood, acrylic, and leather in addition to engraving them.

What safety precautions should be taken when using a laser engraver?

When using a laser engraver, it’s important to wear appropriate eye protection and ensure that the machine is properly ventilated to remove any fumes or smoke produced during the engraving process.

What maintenance is required for a laser engraver?

Regular cleaning and maintenance of the laser engraver’s lens, mirrors, and ventilation system is important to ensure optimal performance and longevity of the machine.

Is training required to use a laser engraver?

While some basic training may be beneficial, many laser engravers are designed to be user-friendly and intuitive to operate, making them accessible to those with little to no experience.