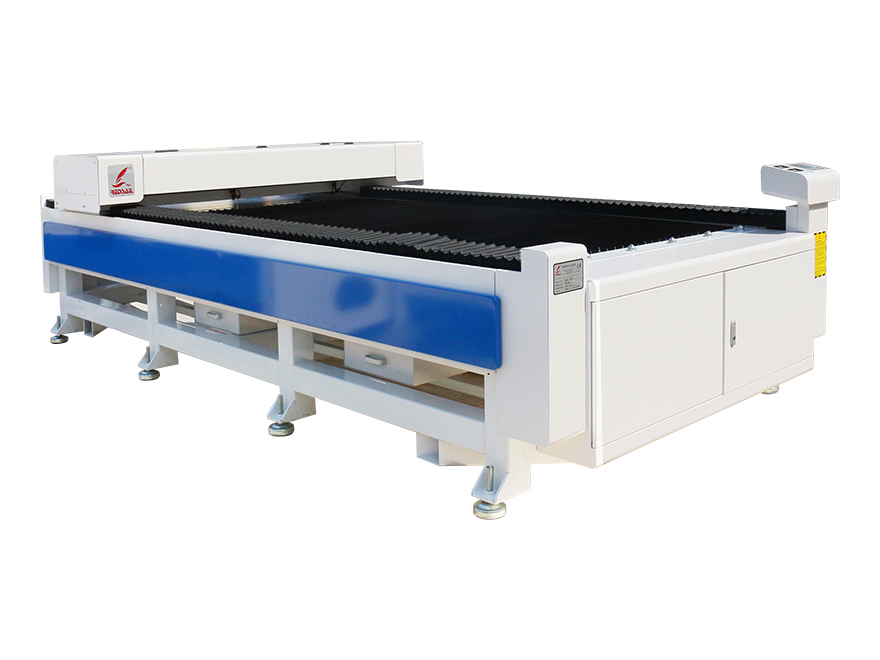

CO2 Laser Cutting: The Benefits of Using Laser Technology for Rubber Cutting

Laser cutting is a popular method for cutting rubber and other materials. It is a precise and efficient way to cut rubber with minimal waste. CO2 laser cutting is a type of laser cutting that uses a CO2 laser to cut rubber. This type of laser cutting is becoming increasingly popular due to its many benefits.

Advantages of CO2 Laser Cutting

CO2 laser cutting offers many advantages over traditional cutting methods. It is a fast and accurate way to cut rubber with minimal waste. The laser beam is able to cut intricate shapes and patterns with ease. The laser beam is also able to cut through thicker materials than traditional cutting methods. This makes it ideal for cutting rubber with complex shapes and patterns.

CO2 laser cutting is also a clean and safe method of cutting rubber. The laser beam does not produce any hazardous fumes or dust, making it a safe option for cutting rubber in enclosed spaces. The laser beam is also able to cut through rubber without producing any heat, which eliminates the risk of burning or melting the rubber.

Cost Savings

CO2 laser cutting is also a cost-effective way to cut rubber. The laser beam is able to cut through rubber quickly and accurately, which reduces the amount of time and labor required to cut the rubber. This can lead to significant cost savings over traditional cutting methods.

The laser beam is also able to cut through thicker materials than traditional cutting methods, which can reduce the amount of material needed for a project. This can lead to further cost savings.

Flexibility

CO2 laser cutting is also a flexible way to cut rubber. The laser beam is able to cut through a variety of materials, including rubber, plastic, and metal. This makes it ideal for cutting rubber with complex shapes and patterns.

The laser beam is also able to cut through thicker materials than traditional cutting methods. This makes it ideal for cutting rubber with intricate shapes and patterns.

FAQs

What is CO2 laser cutting?

CO2 laser cutting is a type of laser cutting that uses a CO2 laser to cut rubber. It is a precise and efficient way to cut rubber with minimal waste.

What are the advantages of CO2 laser cutting?

CO2 laser cutting offers many advantages over traditional cutting methods. It is a fast and accurate way to cut rubber with minimal waste. The laser beam is able to cut intricate shapes and patterns with ease. The laser beam is also able to cut through thicker materials than traditional cutting methods. This makes it ideal for cutting rubber with complex shapes and patterns.

Is CO2 laser cutting cost-effective?

Yes, CO2 laser cutting is a cost-effective way to cut rubber. The laser beam is able to cut through rubber quickly and accurately, which reduces the amount of time and labor required to cut the rubber. This can lead to significant cost savings over traditional cutting methods.