When it comes to laser cutting and engraving, there are different types of laser technologies available. Two popular options are CNC laser and CO2 laser. While both are effective tools for various applications, they have different characteristics and capabilities. Let’s take a closer look at the differences between CNC laser and CO2 laser. CNC Laser...

Month: December 2023

The Ultimate Guide to the Best Laser Engravers of 2023

Introduction Laser engravers have become increasingly popular in recent years due to their ability to create precise and intricate designs on various materials. Whether you’re a hobbyist, a small business owner, or a professional craftsman, investing in a high-quality laser engraver can take your projects to the next level. In this ultimate guide, we’ll explore...

Optimizing CO2 Laser Cut Quality with Troubleshooting

Optimizing CO2 Laser Cut Quality with Troubleshooting In recent years, CO2 laser cutting technology has become a popular choice for a wide range of manufacturing industries due to its precision, speed, and versatility. However, achieving the best possible cut quality with a CO2 laser cutter requires careful optimization and troubleshooting to overcome any issues that...

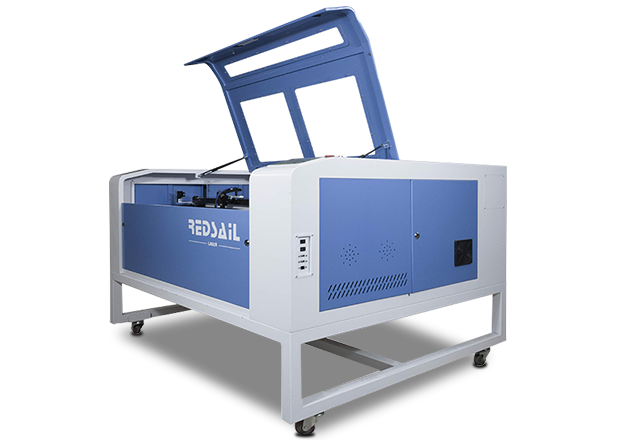

The Best CO2 Laser Engravers for Your Business

CO2 laser engravers are a versatile and efficient tool for businesses looking to add a personal touch to their products. Whether you’re a small crafts business or a large manufacturing company, investing in a CO2 laser engraver can help you create custom designs and add value to your products. Here are some of the best...

A Guide to Choosing Between Plasma Cutters and CO2 Lasers

Introduction When it comes to cutting metal, two of the most popular options are plasma cutters and CO2 lasers. Both of these tools have their own pros and cons, and choosing between them can be a bit confusing. In this guide, we will explore the differences between plasma cutters and CO2 lasers, and help you...

How to Choose the Right CO2 Laser Engraver

When it comes to choosing a CO2 laser engraver, there are a lot of factors to consider. From the size and power of the machine to the software and accessories available, it can be overwhelming to know where to start. In this article, we’ll break down the key factors to consider when choosing a CO2...

A Closer Look at the CO2 Laser Cutter’s Operating Principle

A CO2 laser cutter is a powerful tool used in various industries for cutting and engraving a wide range of materials. Understanding its operating principle is essential for anyone looking to use this technology effectively. In this article, we will take a closer look at the operating principle of a CO2 laser cutter and how...

Where to Find the Best CO2 Laser Engraver

If you are looking for a high-quality CO2 laser engraver, you may be wondering where to find the best one. There are many options available on the market, so it’s important to do your research and find a reputable seller. Below are some tips to help you find the best CO2 laser engraver for your...

CO2 Laser Cutting: Achieving Perfection with Polyimide

CO2 laser cutting is a versatile and efficient method for cutting a wide range of materials, including polyimide. Polyimide is a high-performance polymer known for its thermal stability, excellent mechanical properties, and chemical resistance. When precision cutting is required, CO2 laser technology offers a perfect solution for achieving intricate shapes and precise dimensions in polyimide...

How to Maintain a 100W CO2 Laser Engraver

Introduction A 100W CO2 laser engraver is a powerful tool that can be used for a variety of applications, including cutting and engraving materials such as wood, acrylic, and leather. To ensure that your laser engraver continues to operate at peak performance, it’s important to properly maintain and care for the machine. Here are some...