Introduction

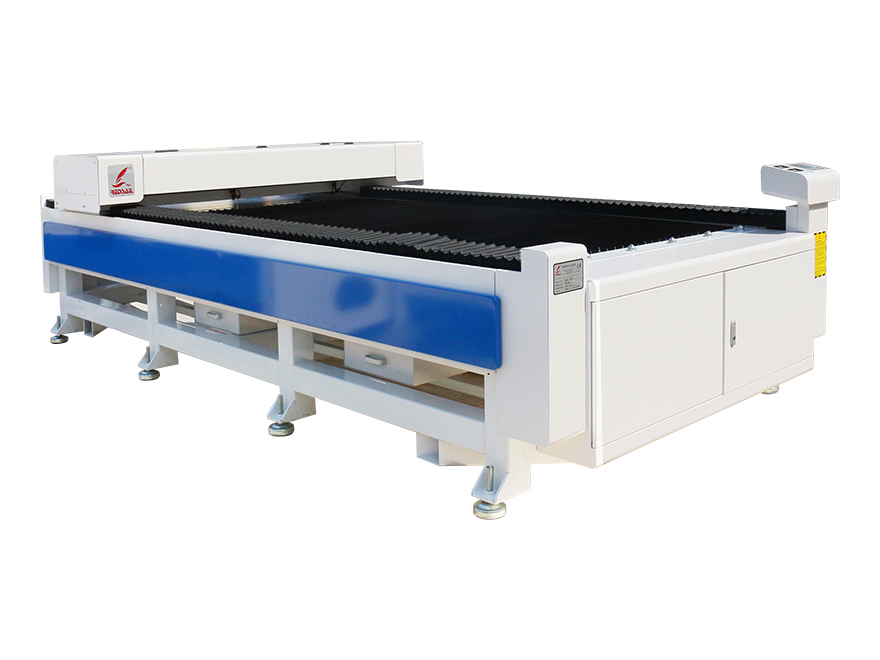

CO2 laser cutters have become an essential tool in the manufacturing industry, offering a wide range of benefits for businesses in Singapore. From precise cutting to efficient production, CO2 laser cutters have revolutionized the way companies operate, allowing for increased productivity and reduced production costs. In this article, we will explore the benefits of CO2 laser cutters in Singapore and how businesses can unlock their full potential.

Precision Cutting

One of the key benefits of CO2 laser cutters is their ability to deliver precise and accurate cuts. This level of precision is crucial for industries such as electronics, aerospace, and medical devices, where even the smallest deviation can lead to product defects. CO2 laser cutters allow for intricate designs and shapes to be cut with minimal margin of error, ensuring high-quality products and customer satisfaction.

Efficiency and Speed

CO2 laser cutters are also known for their efficiency and speed, allowing for rapid production and turnaround times. With the ability to cut through various materials such as metal, wood, plastic, and glass, CO2 laser cutters enable businesses to streamline their production processes and meet tight deadlines. This increased efficiency not only improves productivity but also reduces manufacturing costs, ultimately leading to better profitability for businesses in Singapore.

Versatility

Another benefit of CO2 laser cutters is their versatility. These machines can be used for a wide range of applications, including cutting, engraving, etching, and marking. This versatility allows businesses to diversify their product offerings and cater to different market demands, ultimately expanding their customer base and increasing their revenue streams.

Reduced Material Waste

CO2 laser cutters operate with minimal material wastage, resulting in cost savings for businesses. Traditional cutting methods often result in significant material wastage, which can be costly and unsustainable. CO2 laser cutters, on the other hand, minimize material waste by optimizing the cutting process, ultimately leading to better resource utilization and environmental sustainability.

Conclusion

CO2 laser cutters have transformed the manufacturing industry in Singapore, offering a wide range of benefits for businesses. From precision cutting to speed and efficiency, CO2 laser cutters have enabled businesses to improve their production processes and remain competitive in the market. By embracing the full potential of CO2 laser cutters, businesses in Singapore can unlock new opportunities for growth and success.

FAQs

What materials can CO2 laser cutters work with?

CO2 laser cutters can work with a variety of materials, including metal, wood, plastic, glass, and more.

Are CO2 laser cutters suitable for small businesses?

Yes, CO2 laser cutters are suitable for small businesses, offering cost-effective solutions for precision cutting and production.

How can businesses in Singapore benefit from CO2 laser cutters?

Businesses in Singapore can benefit from CO2 laser cutters by improving their production processes, increasing efficiency, and expanding their product offerings.