Keep exploring at https://brilliant.org/MichaelRechtin/. Get started for free, and hurry—the first 200 people get 20% off an annual …

UCHS55yDvORmCpbM_3vNQQsQ

co2 laser cutter

#LASER #CUTTER.. #Here39s #DIY #CO2 #Laser

Tag Archives: Engraving

Diode vs Co2 Laser Cutting and Engraving: BEFORE YOU BUY!

Watch this video before you buy a laser cutter or engraver. I go over the many differences between the two, and I may save you …

UCQ5V0aJ7pgSoHqYTONUyjrQ

co2 laser engraver

#Diode #Co2 #Laser #Cutting #Engraving #BUY

Laser Engraved Smith & Wesson M&P 9mm SHIELD EZ M2.0

Laser Engraving Vector Design Files for this Build now available!

UCBNAZeQsGbFm2joS9c7JKgA

laser engraved

#Laser #Engraved #Smith #amp #Wesson #MampP #9mm #SHIELD #M2.0

Two Trees TS2 Laser Engraver and Cutter with Z-Axis Auto Focus | Unboxing, Setup & My Experience

Two Trees TS 2 Features:

10W Laser Power – Advanced LD+FAC+C-lens technology enables the spot reach up to 0.08 mm, and get much cleaner, thinner, smoother, deeper cuts. Autofocus laser, no need of manual adjustment. One off cutting of 8mm Plywood, able to cut off 18mm acrylic plate (black) and plywood by several times.

Two Trees TS2 – https://bit.ly/3TeeHho

Two Trees TS3 – https://bit.ly/3BgZLKd

Full Module TS2 Engraver – 60% pre-assembled parts with modular design makes installation easier than ever before. 450x450mm large operate area satisfy your DIY with various material.

New X Y-axis Design – New Y-axis motion structure design ensures it stable and synchronized operation, suitable for high-speed movements. Equipped with X Y axis tensioner which adjusts and tightens the timing belt by the tensioning pulley to improve the precision of the movement.

Offline Engraving & APP Connection – High Speed ESP32-DOWD-V3 Smart Chip, 32-bit LX6 microprocessor, high speed dicing, support LaserGRBL and LightBurn software, makes it more convenient to use by supporting App connection as well. Compatible with windows, MacOS, iOS and Android system.

Top-Notch Safety – Design with flame detector, emergency stop button, Tilt Angle detection and laser protection, we do our best to make sure the machine and objects operate in a safe situation.

Specification:

Model: TS2

Laser Power: 10W

Electrical Requirement: 24V 4A DC

Motherboard: 32 bit

Engraving Speed: 10000mm/min

Engraving Method: USB / APP / Online / Screen Operation

Software Support System: Mac. Windows, Lunix

Laser Wavelength: 445±5nm

Engraving Size: 450x450mm

Machine Weight: 6.5kg

Engraving Materials: Wood, Plastic, Paper, Leather, Bamboo, Stainless Steel, Chevron, Acrylic, Glass, etc

Machine Size: 733x721x172mm

Engraving Mode: Image carving/Text carving /Scanning carving/Contour carving

File Format: SVG. NC. BMP, JPG, PNG, GCODE etc

Support Software: LaserGRBL. Lightburn

Software Support Language: English,German, Italian, French, Chinese

Package Size: 76 x 23 x 34.5cm/30 x 9 x 13.7in

Package Weight: 12.5kg/27.5lb

Visit – http://nisalhe.com/

Follow me on

▶ Instagram – https://instagram.com/nisal_hewagamage

▶ Facebook – https://facebook.com/Nisal.Hewagamage

Contact – hewagamagenisal189gmail.com

For Promotions and Business inquiries – 074 1002929

Intro Credits – https://youtube.com/channel/UC6Y2fMWDKa2A9AWnHjvFm9w

UCa2lHajCato5iXUZ3WPE4Tw

laser engraver

#Trees #TS2 #Laser #Engraver #Cutter #ZAxis #Auto #Focus #Unboxing #Setup #amp #Experience

Amazing laser marking machine, fiber laser engraving. With fiber laser engraving settings

To get the best fiber laser engraving settings, visit: https://barchlaser.com/laser-engraving-settings/

Laser engraving machine for high speed engraving of metals, wood, plastics, glass, and much more.

for more information contact us at https://barchlaser.com/

UC7YeJuYLFpytncFnSoV9fZw

laser marking

#Amazing #laser #marking #machine #fiber #laser #engraving #fiber #laser #engraving #settings

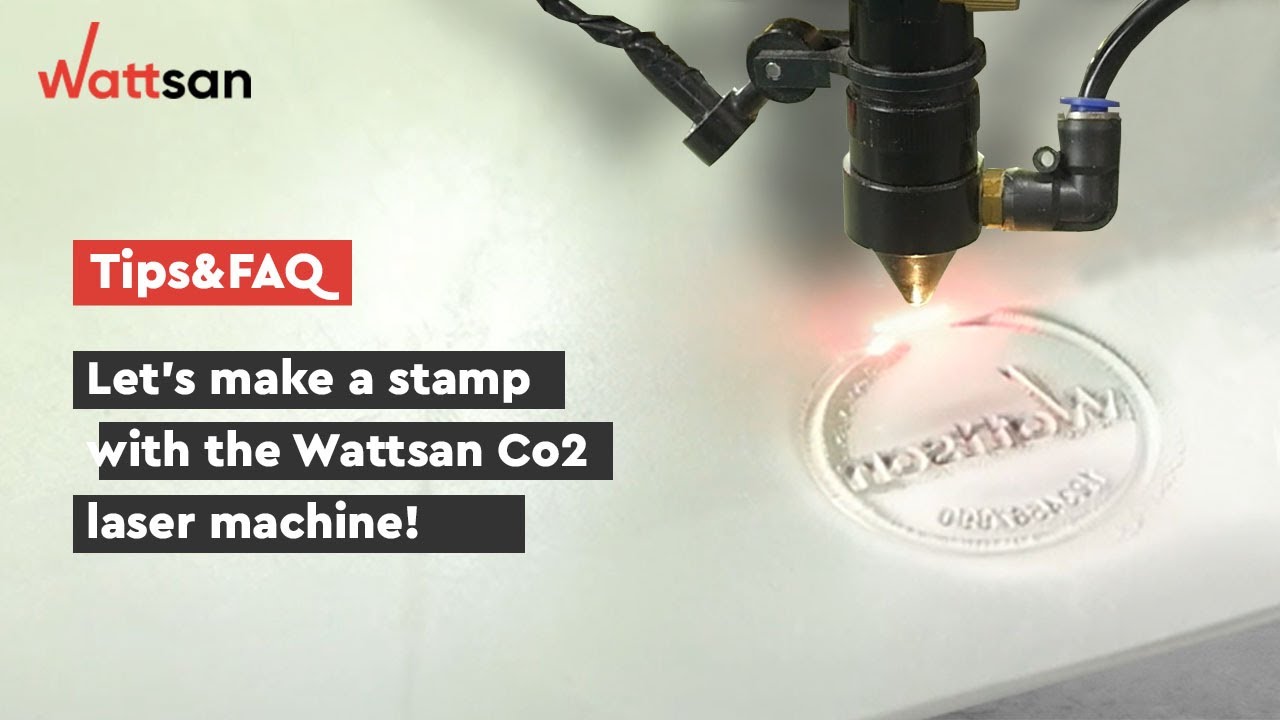

Let's make a stamp with the Wattsan CO2 laser machine!

In this video we tried to show how to make a stamp with the Wattsan CO2 laser machine. If this video was helpful and you want more, don’t forget to follow us and like our videos.

? Production of stamp on a Wattsan laser machine

✔️Let’s start by preparing the model.

✔️For this, you can use any vector program, for example CorelDraw.

✔️Please note that the cutting model must be mirrored.

✔️Next, import the model to the RDWorks program.

✔️Add an additional outline to change the way of engraving.

✔️Set up the engraving parameters for the red color.

✔️With the Reci W2 90W laser tube, we set the speed to 100 mm / s and the power to 25%.

✔️You can change the parameters both in the settings window and directly in the auxiliary window.

✔️Change the engraving speed to 200 mm / s.

✔️Set the parameters of the black color for cutting, set the speed to 15 mm / s and power to 80-85%.

✔️Set the air pressure for blowing in the range of 0.5-1 atmospheres.

✔️Adjust the focal length.

✔️Start engraving.

✔️Pay attention to the quality: the drawing must be clear, the edges must be not fused.

✔️When finished, remove any remaining plaque with a brush or compressed air.

✔️The stamp is ready!

————————————————–

To learn more how to choose a laser machine for your tasks or how to work with the other materials, please follow us.

If you need advice on laser or milling equipment, you can contact Wattsan.

❗For any questions please feel free to contact our customer support. It is there for you 24/7:

+8613153105797

infowattsan.com

————————————————–

? FOLLOW US

Facebook: https://facebook.com/cncwattsan

Instagram: https://instagram.com/wattsancnc

Pinterest: https://pinterest.com/wattsanlaser

UCmFeSsoTtHkkTg_4-09rQ-g

co2 laser

#Let39s #stamp #Wattsan #CO2 #laser #machine

In the Cut – Laser Engraved Leather Baseball

On this episode of In the Cut, we engrave the Area 51 baseball team logo on a leather baseball! Seems appropriate, don’t you agree?

UCEq3boI3lBW0A34xm7yt4RA

laser engraved

#Cut #Laser #Engraved #Leather #Baseball

3D camera and 3D laser engraving machine.

With a 3D camera, it’s much easier to get 3D material into your 3D laser engraving machine.

UCN3EDBD5Z1WcNf8sT_Jjv_A

laser engraving machine

#camera #laser #engraving #machine

Bespoke Airsoft Fiber Laser Engraving

Just a small peak into the capabilities of our fiber laser engraving service.

UC7rRjtq01NYHKNrr4I1Fr0g

laser engraving

#Bespoke #Airsoft #Fiber #Laser #Engraving

Improve Engraving Quality (Correct Scan Offset) on CNC Co2 Laser RD Works/LightBurn Software Config

“When laser scans the graphics in two-way maybe cause the edge of the scanned graphics

uneven due to the relationship between the machine belt tensions. Therefore, increase backlash to correct it. It has the specific backlash for the certain speed. Generally, the faster the speed, the greater the backlash.” (Ref: RD Works User Manual) – Note this is known as Scan Offset Adjustment. I use both terms, however there is a difference in backlash which I plan to discuss in a future video.

Laser Cutting Resources – https://amzn.to/2RNNCUj

Shop Co2 Laser On Amazon – https://amzn.to/2xg7fuY

In this video I explain how you can adjust the reverse offset feature (aka backlash) in RDWorks and LightBurn to improve the quality of your engraving at set speeds.

It is important to note that these fine tuning adjustments are only made to the engraving speeds that you use most and will need to be adjusted for every speed you use. For example if you engrave regularly at 300mm/sec and you make the adjustments for the speed of 300mm/sec these adjustments only take effect when 300mm/sec are used on a layer. That means if you change the engraving speed to 299 or 301mm/sec then the reverse offset adjustments are no longer in effect.

So with that in mind, let us look at how we go about adjusting and fine tuning these to our requirements.

I have set the line interval on this test to 0.5 mm so it separates the lines and you can see them more clearly.

If the backlash is not corrected it can produce poor quality engraving. Something to note is it common for the step distance to be greater for increasing speeds, for example a 600mm/second line has a greater step and therefore each speed will need to be fine tuned individually. So it is only necessary to fine tune these reverse offset adjustments for the engraving speeds that you use.

I hope this video is useful. If you have suggestions for other videos of tips and tricks on the Co2 Laser, send me an (address below) and I will see if I can make time to produce one for that topic.

Recorded with a Logitech C922 – https://amzn.to/2NcR5Nw

Thanks for Visiting.

Until next time, take care

Cheers Matthew

(MW Laser)

Visit Matt’s Workshop at MW Laser : https://mwlaser.com.au/

Instagram https://instagram.com/mattsworkshop/

Facebook https://facebook.com/mattsworkshopau

== If you’d like to support my channel financially so I can continue to produce content you can do via PayPal here — https://paypal.me/mattsworkshop — Thank You ====

Any questions please feel free to me mattmwlaser.com.au or leave a comment below.

NOTE: This is not a paid production or advertisement.

UCYmaUPBZ6oF_OExb3htzTOw

co2 laser

#Improve #Engraving #Quality #Correct #Scan #Offset #CNC #Co2 #Laser #WorksLightBurn #Software #Config