Category Archives: Laser Cutter News

New Upgrades Make CO2 Laser Cutters More Efficient and Effective

New Upgrades Make CO2 Laser Cutters More Efficient and Effective

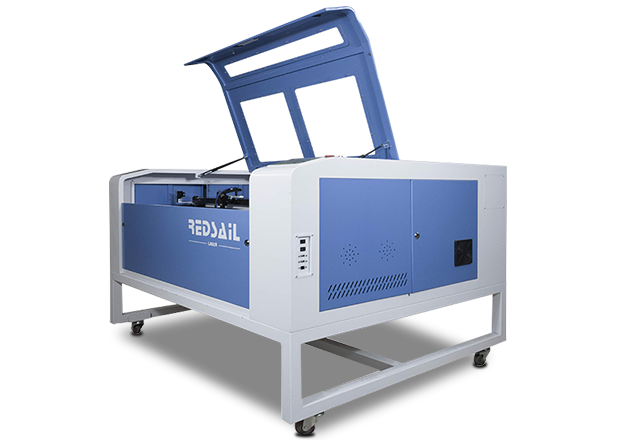

CO2 laser cutters are a popular tool for cutting and engraving a variety of materials. They are used in a variety of industries, from automotive to aerospace, and are becoming increasingly popular in the home workshop. As technology advances, so do the capabilities of these machines. Recent upgrades to CO2 laser cutters have made them more efficient and effective than ever before.

Improved Cutting Speed

One of the most significant upgrades to CO2 laser cutters is the improved cutting speed. Newer models are able to cut faster and more accurately than ever before. This is due to the improved optics and laser power of the machines. The improved optics allow for more precise cutting and the increased laser power allows for faster cutting speeds. This makes CO2 laser cutters more efficient and effective for a variety of applications.

Enhanced Safety Features

Another upgrade to CO2 laser cutters is the enhanced safety features. Newer models are equipped with safety features such as laser interlocks, emergency stop buttons, and automatic shut-off systems. These features help to ensure that the machine is operated safely and that any potential hazards are minimized. This makes CO2 laser cutters safer to use and more reliable for a variety of applications.

Improved Software

The software that controls CO2 laser cutters has also been improved. Newer models are equipped with more advanced software that allows for more precise and accurate cutting. This makes it easier to create complex designs and shapes with the machine. The improved software also makes it easier to program the machine for different materials and applications.

Conclusion

CO2 laser cutters are becoming increasingly popular for a variety of applications. Recent upgrades to the machines have made them more efficient and effective than ever before. The improved cutting speed, enhanced safety features, and improved software make CO2 laser cutters a great choice for a variety of applications.

in industry

The Impact of Industry on the Economy

Industry plays a major role in the economy of any nation. It is responsible for the production of goods and services, which are essential for the growth and development of a country. Industry is also responsible for providing employment opportunities to people, which in turn helps to increase the standard of living of the population.

Types of Industry

Industry can be divided into two main categories: primary and secondary. Primary industry involves the extraction of raw materials from the environment, such as mining, forestry, and fishing. Secondary industry involves the processing of these raw materials into finished products, such as manufacturing and construction.

Economic Benefits of Industry

Industry has a number of economic benefits. It provides employment opportunities to people, which helps to reduce unemployment and poverty. It also generates income for the government through taxes, which can be used to fund public services and infrastructure. Furthermore, industry helps to stimulate economic growth by increasing the production of goods and services, which in turn leads to increased demand and higher prices.

Environmental Impact of Industry

Industry can also have a negative impact on the environment. The extraction of raw materials can lead to deforestation, pollution, and the destruction of habitats. The processing of these materials can also lead to air and water pollution, as well as the release of hazardous chemicals into the environment.

Conclusion

Industry plays an important role in the economy of any nation. It provides employment opportunities and generates income for the government. However, it can also have a negative impact on the environment, so it is important to ensure that industry is managed responsibly.

Revolutionizing Manufacturing: The Benefits of CO2 Laser Cutting

Revolutionizing Manufacturing: The Benefits of CO2 Laser Cutting

Manufacturing has come a long way since the days of manual labor and traditional tools. Today, manufacturers are turning to advanced technologies such as CO2 laser cutting to revolutionize their production processes. CO2 laser cutting is a process that uses a beam of high-intensity light to cut through materials such as metal, plastic, and wood. This technology offers a number of benefits that make it an attractive option for manufacturers.

Precision and Accuracy

One of the biggest advantages of CO2 laser cutting is its precision and accuracy. The laser beam is able to cut materials with a high degree of accuracy, which is essential for many manufacturing processes. This accuracy also helps to reduce waste, as the laser can cut materials to exact specifications.

Flexibility

CO2 laser cutting is also highly flexible. The laser can be used to cut a variety of materials, including metals, plastics, and wood. This makes it an ideal choice for manufacturers who need to produce a wide range of products.

Speed

CO2 laser cutting is also much faster than traditional cutting methods. The laser beam is able to cut through materials quickly and efficiently, which helps to reduce production times and increase efficiency.

Cost Savings

CO2 laser cutting can also help manufacturers save money. The laser is able to cut materials with a high degree of accuracy, which reduces the amount of waste produced. This helps to reduce costs associated with materials and labor.

Safety

CO2 laser cutting is also much safer than traditional cutting methods. The laser beam is contained within the machine, which eliminates the risk of injury from flying debris. This makes it an ideal choice for manufacturers who need to ensure the safety of their workers.

Conclusion

CO2 laser cutting is a revolutionary technology that offers a number of benefits for manufacturers. It is precise, flexible, fast, and cost-effective, and it also helps to ensure the safety of workers. For these reasons, it is an attractive option for manufacturers who are looking to revolutionize their production processes.

Revolutionary CO2 Laser Technology Cuts Through Metal with Ease

Revolutionary CO2 Laser Technology Cuts Through Metal with Ease

Introduction

The use of lasers in industrial applications has been steadily increasing over the past few decades. One of the most popular types of lasers used in industrial applications is the CO2 laser. This type of laser is capable of cutting through a variety of materials, including metal. In this article, we will discuss the advantages of using CO2 lasers for cutting metal and how this revolutionary technology is revolutionizing the metalworking industry.

What is a CO2 Laser?

A CO2 laser is a type of laser that uses a mixture of carbon dioxide and other gases to generate a beam of light. This beam of light is then focused onto a target material, such as metal, and is used to cut or engrave the material. CO2 lasers are highly efficient and can cut through metal with ease.

Advantages of Using CO2 Lasers for Cutting Metal

There are several advantages to using CO2 lasers for cutting metal. First, CO2 lasers are highly efficient and can cut through metal quickly and accurately. This makes them ideal for industrial applications where speed and accuracy are essential. Additionally, CO2 lasers are capable of cutting through a variety of metals, including stainless steel, aluminum, and titanium.

Another advantage of using CO2 lasers for cutting metal is that they produce very little heat. This makes them ideal for cutting delicate materials, such as thin sheet metal, without damaging the material. Additionally, CO2 lasers are capable of producing intricate designs and patterns on metal surfaces.

Conclusion

CO2 lasers are revolutionizing the metalworking industry. They are highly efficient and can cut through a variety of metals with ease. Additionally, they produce very little heat, making them ideal for cutting delicate materials. Finally, CO2 lasers are capable of producing intricate designs and patterns on metal surfaces. For these reasons, CO2 lasers are becoming increasingly popular in the metalworking industry.

Where to Find the Best Deals on CO2 Laser Cutters

Where to Find the Best Deals on CO2 Laser Cutters

CO2 laser cutters are a great tool for any business or hobbyist looking to make precise cuts in a variety of materials. They are becoming increasingly popular due to their versatility and affordability. However, finding the best deals on CO2 laser cutters can be a challenge. In this article, we will discuss some of the best places to find great deals on CO2 laser cutters.

Online Retailers

Online retailers are a great place to start when looking for the best deals on CO2 laser cutters. Many online retailers offer discounts and promotions on their products, so it’s worth taking the time to compare prices and features. Additionally, many online retailers offer free shipping and returns, so you can be sure you’re getting the best deal.

Manufacturers

Another great place to look for the best deals on CO2 laser cutters is directly from the manufacturer. Many manufacturers offer discounts and promotions on their products, so it’s worth taking the time to compare prices and features. Additionally, many manufacturers offer free shipping and returns, so you can be sure you’re getting the best deal.

Local Stores

Local stores are another great place to look for the best deals on CO2 laser cutters. Many local stores offer discounts and promotions on their products, so it’s worth taking the time to compare prices and features. Additionally, many local stores offer free shipping and returns, so you can be sure you’re getting the best deal.

Conclusion

Finding the best deals on CO2 laser cutters can be a challenge, but it’s worth taking the time to compare prices and features. Online retailers, manufacturers, and local stores are all great places to look for the best deals on CO2 laser cutters. With a little bit of research, you can be sure you’re getting the best deal on your CO2 laser cutter.

Revolutionary CO2 Laser Technology Enables Metal Cutting

Revolutionary CO2 Laser Technology Enables Metal Cutting

The use of laser technology for metal cutting has been around for decades, but recent advances in CO2 laser technology have revolutionized the process. CO2 lasers are now capable of cutting through a variety of metals with precision and accuracy, making them a valuable tool for a variety of industries.

How Does CO2 Laser Technology Work?

CO2 lasers use a combination of electricity and gas to create a beam of light that is focused on the material to be cut. The beam is so powerful that it can vaporize the material, allowing for precise and accurate cuts. The laser beam is directed by a computer-controlled system, which allows for complex shapes and patterns to be cut with ease.

Benefits of CO2 Laser Technology

CO2 laser technology offers a number of benefits over traditional cutting methods. It is faster and more accurate than traditional methods, and it can be used to cut a variety of metals, including stainless steel, aluminum, and titanium. It also produces less waste and requires less energy than other cutting methods.

Applications of CO2 Laser Technology

CO2 laser technology is used in a variety of industries, including automotive, aerospace, and medical. It is used to cut and shape metal components for cars, airplanes, and medical devices. It is also used to create intricate patterns and designs on metal surfaces.

Conclusion

CO2 laser technology has revolutionized the metal cutting industry. It is faster, more accurate, and more efficient than traditional methods, and it can be used to cut a variety of metals with precision and accuracy. It is an invaluable tool for a variety of industries, and its use is only expected to grow in the future.