Unlock the Possibilities of CO2 Laser Cutting with Professional Services

CO2 laser cutting is a powerful and versatile tool for cutting and engraving a variety of materials. It is used in a wide range of industries, from automotive to aerospace, and is becoming increasingly popular for its precision and accuracy. Professional services can help you unlock the full potential of CO2 laser cutting and ensure that your projects are completed to the highest standards.

What is CO2 Laser Cutting?

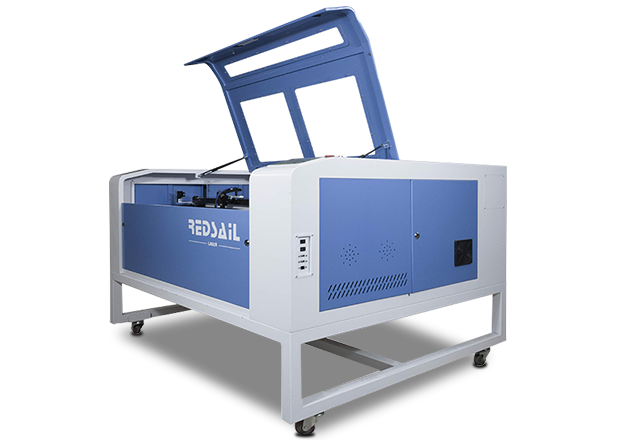

CO2 laser cutting is a process that uses a beam of high-energy laser light to cut and engrave materials. The laser beam is generated by a CO2 laser, which is a type of gas laser that uses carbon dioxide as its active medium. The laser beam is focused onto the material, which is then heated and vaporized, creating a precise cut or engraving.

Benefits of Professional Services

Professional services can help you unlock the full potential of CO2 laser cutting. They can provide expert advice on the best materials and techniques for your project, as well as helping you to select the right equipment and software. They can also provide training and support to ensure that your projects are completed to the highest standards.

Types of Materials

CO2 laser cutting can be used to cut and engrave a wide range of materials, including wood, plastics, metals, and even glass. Professional services can help you select the right material for your project and ensure that it is cut and engraved to the highest standards.

Conclusion

CO2 laser cutting is a powerful and versatile tool for cutting and engraving a variety of materials. Professional services can help you unlock the full potential of CO2 laser cutting and ensure that your projects are completed to the highest standards. They can provide expert advice on the best materials and techniques for your project, as well as helping you to select the right equipment and software.